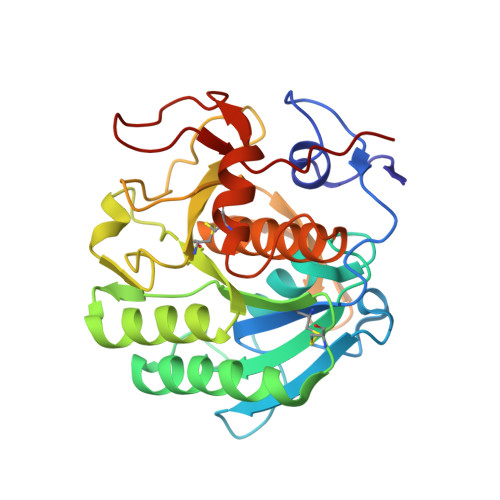

Using sound pulses to solve the crystal-harvesting bottleneck.

Samara, Y.N., Brennan, H.M., McCarthy, L., Bollard, M.T., Laspina, D., Wlodek, J.M., Campos, S.L., Natarajan, R., Gofron, K., McSweeney, S., Soares, A.S., Leroy, L.(2018) Acta Crystallogr D Struct Biol 74: 986-999

- PubMed: 30289409

- DOI: https://doi.org/10.1107/S2059798318011506

- Primary Citation of Related Structures:

5WHW, 5WJG, 5WJH - PubMed Abstract:

Crystal harvesting has proven to be difficult to automate and remains the rate-limiting step for many structure-determination and high-throughput screening projects. This has resulted in crystals being prepared more rapidly than they can be harvested for X-ray data collection. Fourth-generation synchrotrons will support extraordinarily rapid rates of data acquisition, putting further pressure on the crystal-harvesting bottleneck. Here, a simple solution is reported in which crystals can be acoustically harvested from slightly modified MiTeGen In Situ-1 crystallization plates. This technique uses an acoustic pulse to eject each crystal out of its crystallization well, through a short air column and onto a micro-mesh (improving on previous work, which required separately grown crystals to be transferred before harvesting). Crystals can be individually harvested or can be serially combined with a chemical library such as a fragment library.

Organizational Affiliation:

Office of Educational Programs, Brookhaven National Laboratory, Upton, NY 11973-5000, USA.